Energy Intensive Industries

Energy-intensive industries include those sectors whose production processes require high energy use. These industries include sectors such as building materials, chemicals, glass, non-ferrous metals, paper and steel. The production processes require typically high amounts of electricity, heat and/or steam. In view of rising energy costs and the effects of emissions on the climate, it is therefore essential to improve and optimize the processes and the individual system components.

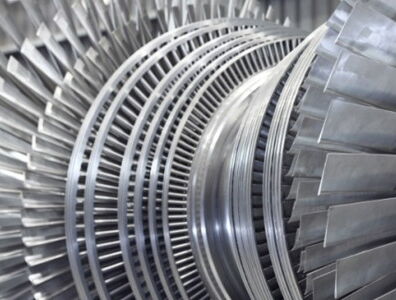

Turbo machines for compression or expansion are often important components in these processes. In addition, residual heat, steam or compressed gases in the production processes are often available as additional output, which are not yet used or not optimally used. This would be possible by further processes also including turbo machines. B&B-AGEMA is experienced in design and upgrade of such turbo machines including for example industrial compressor or blowers, top-pressure recovery turbines or small-sized steam turbines.

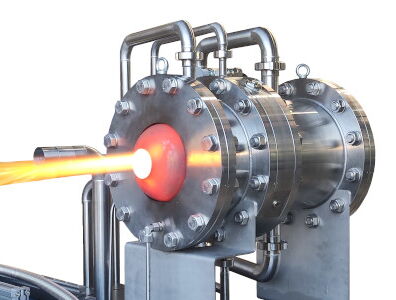

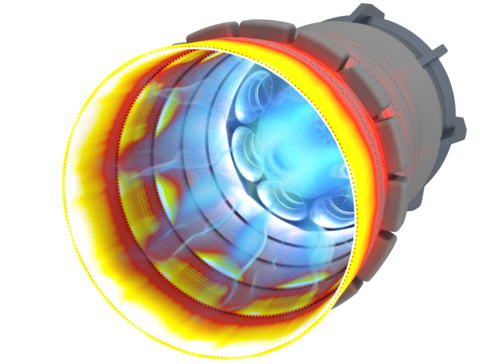

Industrial burners are also often included in production processes, e.g. in metal treatment ovens. Beside the optimization of such burners and combustion processes, a major challenge is often to switch to high Hydrogen content fuel gases and make the combustion technology “Hydrogen-ready”. B&B-AGEMA is experienced in design and development of new combustion technologies by means of modern combustion simulations.

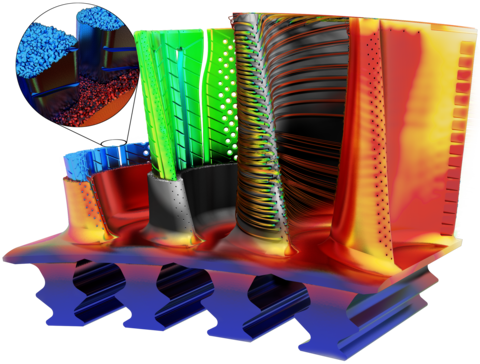

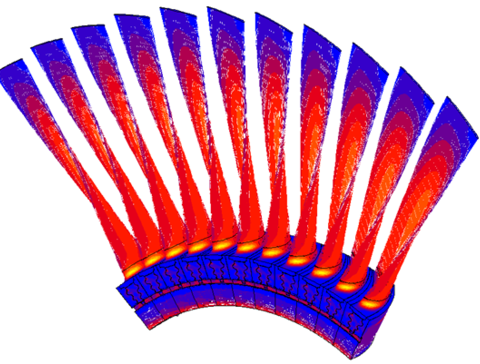

Fluid flow simulations including optimization of flow paths as well as thermomechanical analyses and design of high-temperature components are typical examples of our project work. B&B-AGEMA has performed a wide range of projects for clients in the fields of chemical industry, process engineering, energy- and environment engineering and apparatus engineering.