Fluid Flow & Heat Transfer

The application of Computational Fluid Dynamics (CFD) software is a modern and powerful investigation method of complex realistic flows in order to achieve the understanding of flow phenomena. Therefore, such modern tools are today a reliable basis for optimization of configurations with respect to the flow path and associated pressure losses, aerothermal mixing of fluids and combined flow and heat transfer. B&B-AGEMA uses such modern software and tools and offers services on following topics:

- 3-D flow analysis in the fields of power technology, especially in oil & gas technology

- 3-D flow analysis of vehicles including ventilation

- 3-D flow analysis in the surrounding area of buildings

- combustion simulation

- two-phase flow simulation, gas mixtures

- flow in exhaust gas channels

- simulation of free surfaces

- condensation and evaporation

- flow in cooling channels

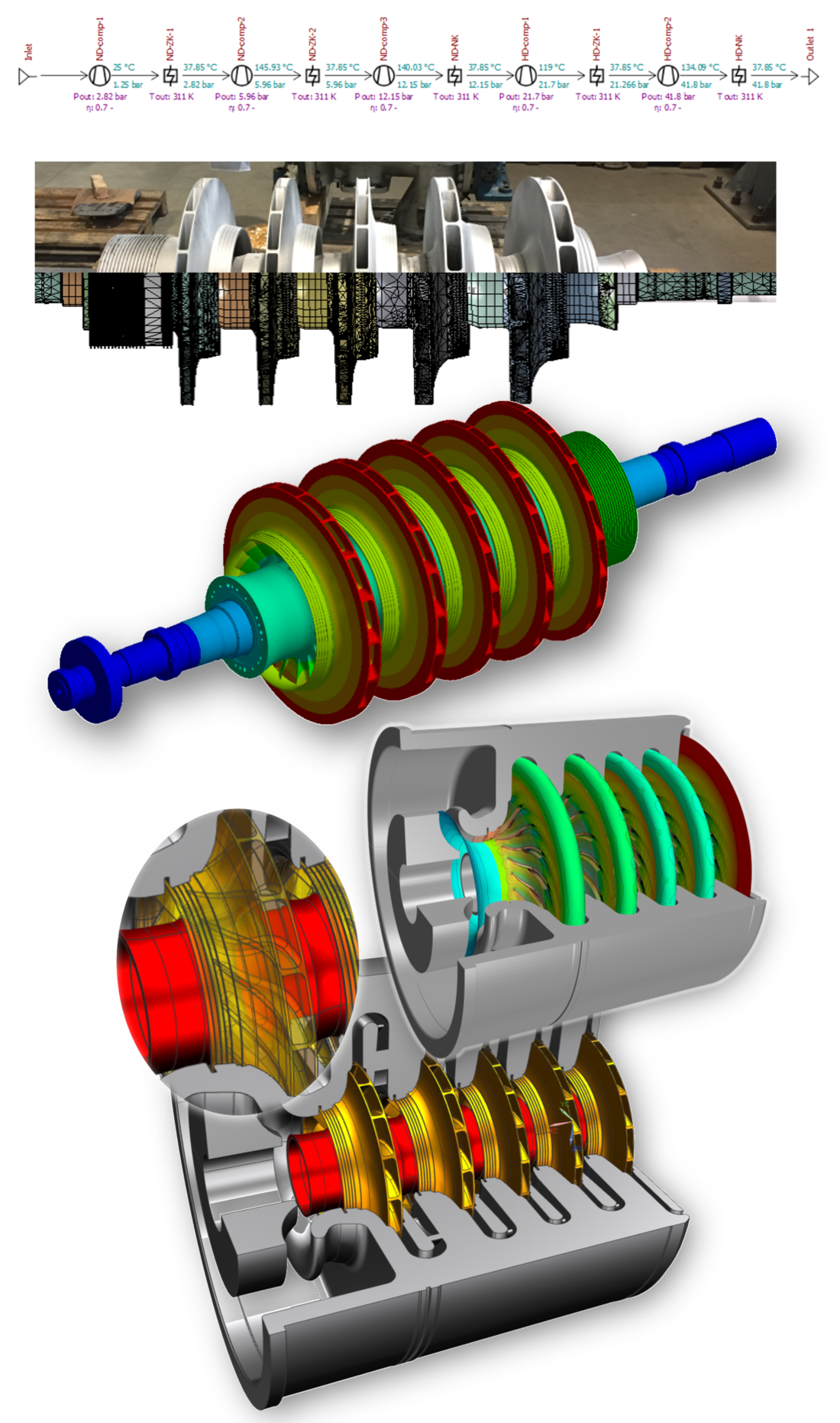

Centrifugal Industrial Gas Compressor Upgrade

Re-engineering of a gas compressor:

- Thermodynamic cycle and process analysis:

- In-house process tools to evaluate stage conditions

- Commercial tools for validation and stage fine turning

- Aerodynamic design:

- Commercial 3D-CFD for new and upgrade design of flow path

- Real gas & multiphase CFD simulation of compressors

- 3D impeller design improvements based on CFD

- Mechanical design:

- Structural investigations on the impeller, volute, housing, ...

- Rotor dynamics

- Vibration and Eigen mode analysis

- Design Process

- Automated Design Workflow with integrated design parameter optimization (e.g. cycle optimization, geometry optimization)

- Managed in HEEDS MDO: an automated design workflow has been established with connection and interaction of several software packages

Examples

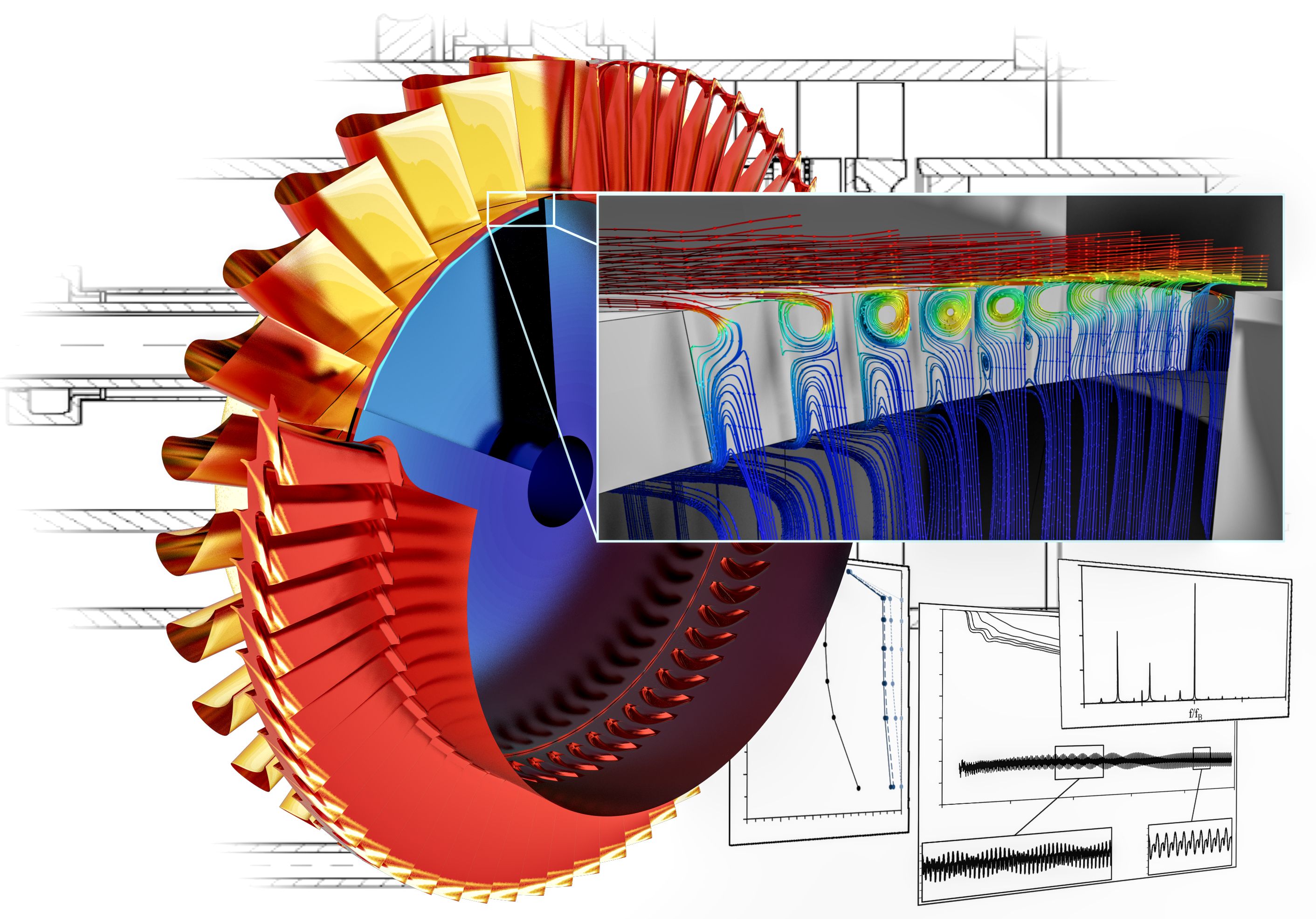

Unsteady Flow Simulation of a Gas Turbine Rim Sealing Configuration

- Full annulus CFD-simulation of one turbine stage including rim sealing

- Static and transient simulation to analyse interaction between main flow and rim sealing flow